Understanding lubricant knowledge in a practical way and applying it efficiently

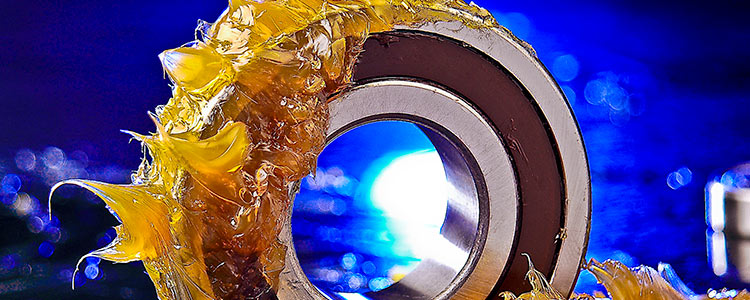

In this comprehensive online video training course, “Basic Lubricant Knowledge for Practitioners,” specialists and managers learn how lubrication really works—from the physical fundamentals to how to read technical data sheets professionally. You will learn why choosing the right lubricant is crucial for the performance, longevity, and cost-effectiveness of machines.

The modular video seminar series comprises three modules that provide practical knowledge on the structure, function, and classification of lubricants—and clearly illustrates when mineral oils, semi-synthetic oils, and fully synthetic oils are best used. With clear examples and tried-and-tested knowledge, this training course supports anyone who wants to improve the efficiency and reliability of technical systems in the long term.

- Deepen understanding of the structure, function, and mode of action of lubricants

- Learn how to competently read and interpret technical data sheets

- Be able to reliably apply and compare lubricant characteristics

- Promoting economical selection and optimal use of modern lubricants

- Reduce damage and downtime costs through targeted lubrication

- Specialists and managers from maintenance and servicing

- Service technicians, fitters, and commissioning personnel

- Design engineers, sales and service engineers

- Lubricant sales representatives and technical advisors

- Manufacturer of lubrication systems and technical components

- Technical buyers and experts

- Employees who want to expand their tribological expertise