Target Group

- Maintenance managers and service technicians for wind farms

- Service technicians, fitters and service partners of wind turbine manufacturers

- Managers of wind farms where maintenance work is carried out by their own staff

- Technical specialists from construction, service and sales for wind turbines

- Sales engineers and sellers of lubricating oils and greases

- Manufacturer of main and bypass filters for transmission and hydraulic oils

- Supplier of gearboxes, rolling bearings and components for wind turbines

- Technical purchasers for lubricants and operating fluids

- Technicians in oil change vehicles and in on-site condition monitoring and fluid management

- Appraisors and surveyors for damage analysis and machine malfunction

- Technically interested employees who want to extend their knowledge in the areas lubrication techniques and tribology

Aims

- Know and assess the differences between lubricant types

- Selection of the most suitable lubricant for economical and reliable system operation

- Optimisation and extension of oil change intervals for transmission and hydraulic oils

- Cost reduction and longer oil service life thanks to better filtration and oil maintenance

- Early detection of unusual wear processes and possible faults

- Investigation of causes of faliure after breakdowns

- Extraction of meaningful oil samples

- Oil analysis in pro-active maintenance

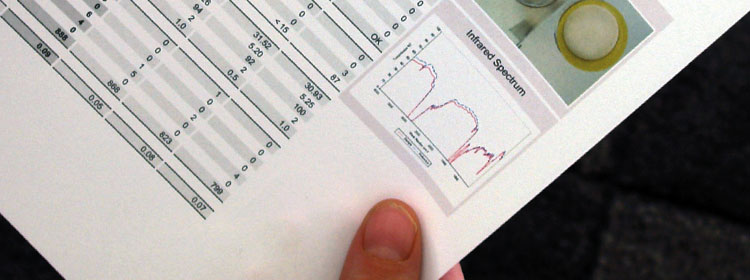

- Interpretation of lab reports

- Warning and limit values for assessing gearbox damage and oil condition

- Advantages and function of multigrade hydraulic oils

- Simplification of grease type selection, optimisation of relubrication intervals

- Warning and limit values for used lubricating greases