The most important facts in brief:

Contamination is by far the most common cause of malfunctions and failures in oil-lubricated machines and hydraulic systems. Adequate cleanliness of lubricating and hydraulic oils is often seen as a necessary evil rather than the key to trouble-free operation. At the same time, excessive purity requirements can be found on the market, which are partly born out of uncertainty and partly out of commercial interests.

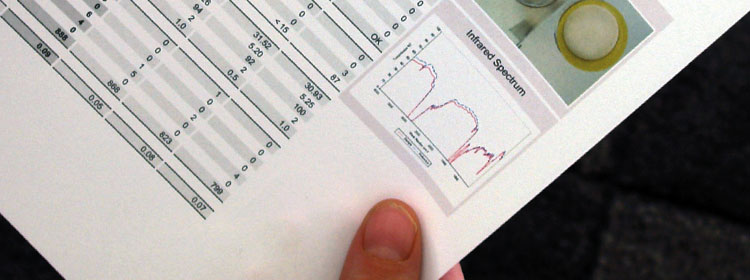

Particle counting, including particle counting, is used more than almost any other method. of the purity class is often misunderstood and misinterpreted in practice. Different counting methods can lead to different purity classes, which are often attributed to the sampling alone. However, particle counting and cleanliness class require a special interpretation in comparison to other test methods, such as viscosity, which takes into account the nature of these counting methods in order to be successfully applied in practice.