The most important facts in brief:

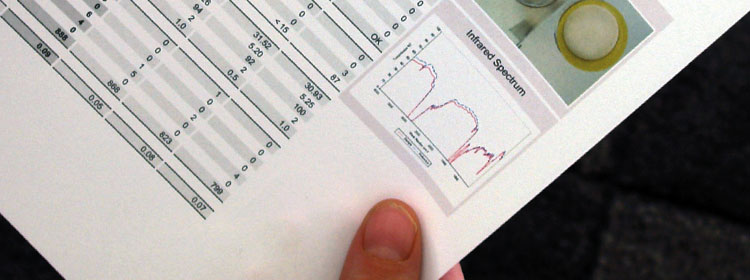

The formation of oil ageing products is a normal consequence of operational stress on the oil. Ageing can often be seen with the naked eye from the gradually darkening colour of the oil. Routine monitoring of turbine oils is designed to reliably detect these changes. In recent years, there have been an increasing number of cases in which serious faults have occurred, including turbine shutdowns, even though no abnormalities were visible in the classic oil monitoring parameters. Further investigations showed that the disorders were always associated with the formation of deposits.

In a total of four one-hour modules, the online training series initially deals with the causes and boundary conditions of the formation of deposits in lubricating and control oil systems. The possibilities for recognising, preventing and removing deposits are then discussed in detail.

Target Group

- Skilled employees and executives working in maintenance of power plants and chemical companies

- Service technicians, fitters and commissioning personnel from manufacturers of turbines, turbocompressors and power plants

- Service partners of facility Producers

- Technically skilled employees working in construction, serive and sales

- Sales engineers and sales people of lubricant proucers und their resellers

- Producers of oil circulation and central lubrication systems

- Technical purchasers for lubricants and operating fluids

- Application technician in laboratory vehicles, as well as in on-site condition monitoring and fluid management

- Appraisors and surveyors for damage analysis and machine malfunction

- Technically interested employees who want to extend their knowledge in the areas lubrication techniques and tribology