Commercial vehicles (e.g. buses, lorries/trucks, tractor units, cranes) and mobile machinery (tractors, construction site vehicles such as forklift trucks, dump trucks, snow groomers, as well as municipal vehicles such as refuse collection vehicles, street sweepers, sewer cleaning machines) contain a large number of different assemblies whose reliable function and service life are ensured by the lubricant, and they often work under very different operating conditions. For example, as a long-distance lorry with a high annual mileage, in stop-and-go construction site operations or as a municipal vehicle in seasonal use.

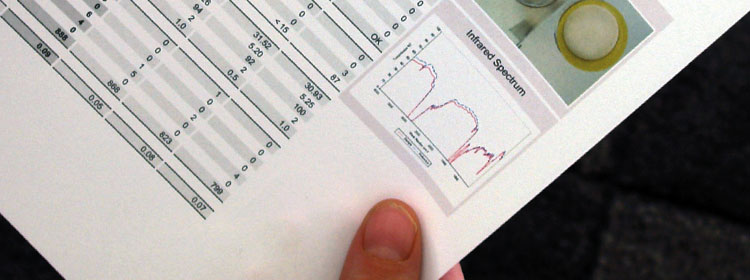

Regular oil monitoring allows the oil change intervals to be adapted to the very different conditions without risk. At the same time, they provide reliable information on abnormal wear processes and the increased entry of impurities. Potenzielle Störungen können frühzeitig erkannt und pro-aktiv behandelt werden.

In this seminar you will learn …

- Which lubricants are used in which components of commercial vehicles or work machines and why

- What are the advantages of synthetic oils and where does their use make sense

- What special features need to be considered when using organic oils

- How the required quality of the lubricants can be safely described

- How professional oil monitoring works and helps you to increase reliability and service life

Target Group

- Specialists and managers from the maintenance and repair of commercial vehicles and mobile machinery

- Technical consultants and sales staff from lubricant and component manufacturers

- Specialists and managers from the service sector in the field of maintenance and servicing, especially of commercial vehicles and mobile machinery