Whether it’s houses, roads, industrial buildings or bridges – construction machinery is an integral part of our lives. The variety of individual types is enormous: excavators, wheel loaders, tippers, concrete mixers or concrete pumps, graders or compactors.

Construction machinery and other mobile equipment contain a large number of different assemblies whose reliable functioning and service life is ensured by the lubricant. Construction machinery also works under adverse conditions: Changing temperatures, moisture and dust, combined with the highest loads.

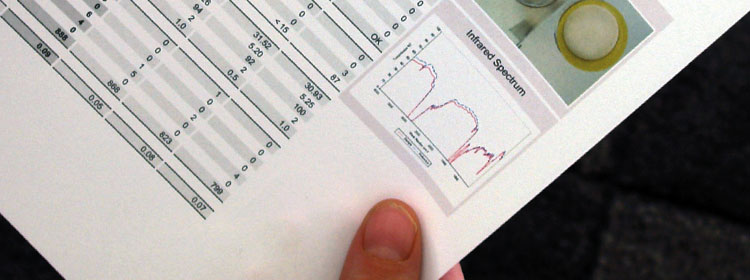

This is why oil monitoring in construction machinery has been so important for many years. Oil analyses not only make it possible to significantly increase the service life of the oil filling. At the same time, they provide reliable information on abnormal wear processes and the increased entry of impurities. Potential faults can be recognised at an early stage and treated proactively.

In this seminar you will learn …

- How lubricants and lubrication work in principle

- Which lubricants are used in which components and why

- What special features need to be considered when using organic oils

- What are the advantages of synthetic oils and where does their use make sense

- How the required quality of the lubricants can be safely described

- How professional oil monitoring works and helps you to increase reliability and availability

- How the professional handling of lubricants avoids recurring practice problems

Target Group

- Specialists and managers from the maintenance and repair of construction machinery

- Technical consultants and sales staff from lubricant and component manufacturers

- Specialists and managers from the service sector for the maintenance and repair of construction machinery