Efficient lubrication and oil monitoring: the key to the longevity of hydroelectric power stations

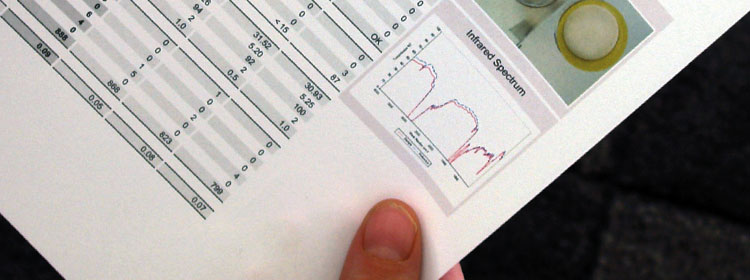

Hydroelectric power stations require special lubricants and precise oil monitoring to ensure their long service life and optimum performance. In our seminar, you will learn how to use oil analyses in a targeted manner to increase the reliability and availability of your equipmen Practical examples show how the correct use of lubricating oils and bio-oils prevents typical problems and makes maintenance more efficient. Benefit from in-depth knowledge that is specifically tailored to the technical characteristics of water turbines.

- Understanding how lubricating and hydraulic oils work in hydroelectric power stations

- Knowledge of the different types of oil and their areas of application

- Recognising the advantages and possible uses of organic oils

- Professional oil monitoring to extend oil service life and increase plant availability

- Avoiding practical problems through optimal use of lubricants

- Specialists and managers from the maintenance and repair of hydroelectric power stations

- Technical consultants and sales personnel from oil companies

- Specialists and managers from oil-related service areas such as oil maintenance and oil change services

- Technical specialists and managers from turbine manufacturers