The most important facts in brief:

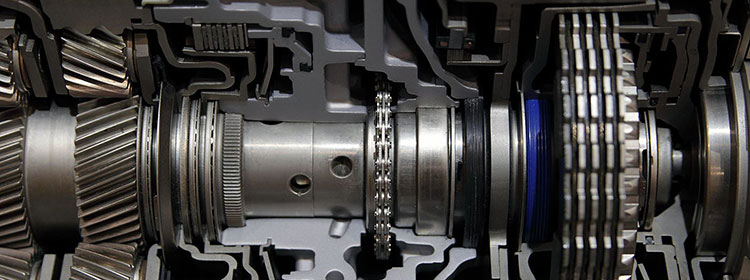

Gearboxes come in a wide variety of shapes and sizes. They work under different operating conditions in continuous or intermittent operation. The individual components of the gearbox are subject to constantly increasing torques, as the components have to become smaller and smaller even with increasing power. The high demands on system reliability and availability require optimum lubrication and professional oil and system monitoring.

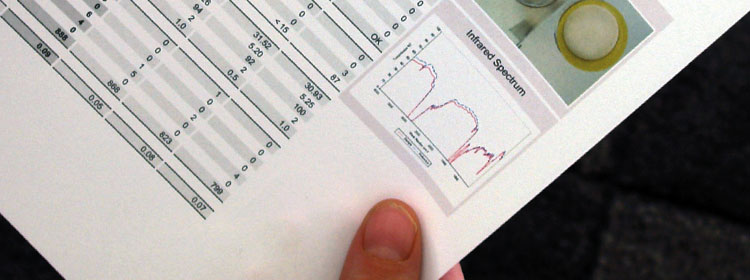

Trend monitoring of the transmission oil also offers an excellent opportunity to recognise irregularities at an early stage and thus increase the service life of the oil and system.

In our online training series, you will learn which parameters you need to monitor in modern transmission oils in addition to the “classics”, what they actually tell you and how practical and valuable recommendations can be derived by correctly linking the individual measured values.

Target Group

- Skilled employees and executives working in the field of maintenance

- Mechanics and service technicians of gear and machinery producers

- Technically skilled employees working in construction, serive and sales

- Sales engineers and sales people of lubricant proucers und their resellers

- Technical purchasers for lubricants and operating fluids

- Application engineers working in mobile labs as well as for on-site condition monitoring and fluid management

- Appraisors and surveyors for damage analysis and machine malfunction

- Technically interested employees who want to extend their knowledge in the areas lubrication techniques and tribology