Online sensors for lubricants are constantly being developed further. The latest generation has sufficient accuracy to transparently display the oil and system status. However, they can only compete with test results from an oil analysis laboratory to a limited extent. But they don’t have to.

The advantage of online oil sensors lies in the permanent data recording, which means that even the slightest trend increases can be detected. But which sensor is suitable for which system? Do all sensors work with every type of oil? How can the generated data be processed, visualised and evaluated?

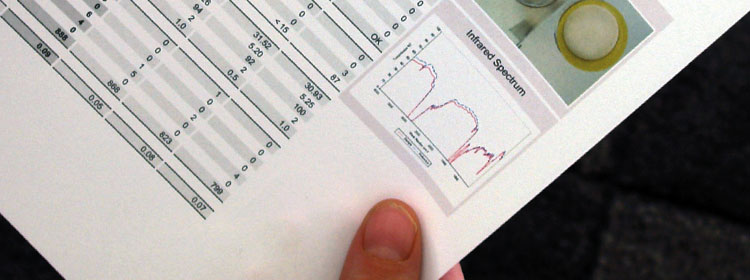

These and many other questions will be answered by your speakers during the two-day seminar “Online oil sensors”. In addition to the lubricant basics and their typical ageing mechanisms during use in the system, different sensor types are presented in detail.

Furthermore, possibilities for data processing and analysis are shown in order to be able to filter as much information as possible from the collected data. The focus will be on multivariate data analysis and how this can be processed using “standard software”, such as MS Excel, but also advanced software tools.

The seminar is aimed at system manufacturers and operators as well as maintenance engineers who are planning or already practising the use of online oil sensors for condition monitoring of their systems.