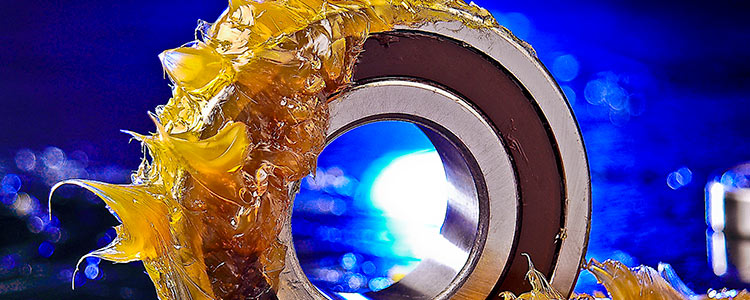

Efficient grease application and monitoring for maximum machine reliability

Expand your expertise on the optimal application and monitoring of lubricating greases with our practical seminar. Learn how to select and use lubricating greases correctly in order to identify lubrication problems early on and remedy them effectively.

Use grease analyses and laboratory results to precisely monitor the condition of your machines and thus minimise downtime. Proper grease monitoring increases the service life and reliability of your equipment while reducing maintenance costs. Improve machine performance in your business now with in-depth knowledge of lubricating grease and secure sustainable efficiency gains.

- Optimal selection of the right lubricating grease for economical and reliable plant operation

- Understanding the influence of grease type and grease quality on relubrication intervals and trouble-free operation

- Professional collection of meaningful fat samples for analysis

- Extension of relubrication intervals through targeted use of grease

- Selection criteria for lubricating greases in central lubrication systems and lubrication devices

- Use of grease analysis as a proactive measure in maintenance

- Competent assessment and interpretation of analysis results

- Application of warning values for early detection of machine damage and grease condition

- Early detection of unusual wear and potential malfunctions

- Systematic investigation of causes of machine failures and lubrication problems

- Specialists and managers from operations and maintenance

- Technical specialists from the design, service and sales departments of bearing and system manufacturers or their service partners

- Sales engineers and sales people of lubricant proucers und their resellers

- Specialists and service personnel from the areas of lubrication systems and lubrication devices

- Technical purchasers of lubricants and operating materials

- Appraisors and surveyors for damage analysis and machine malfunction

- Technically interested employees who want to extend their knowledge in the areas lubrication techniques and tribology