Learn how to determine the optimal time and the correct procedure for changing the oil.

Find out what really matters when determining the right time for an oil change and the best way to do it in our practical video training course “Oil changes – when and how?”. The two-module video training course provides you with in-depth knowledge of oil aging mechanisms, criteria for oil changes, and the technical and economic relationship between change intervals, machine service life, and operational safety.

Using clear practical examples, you will learn how to plan oil changes according to your needs, reduce costs, and ensure the long-term reliability of your systems. This allows you to avoid unnecessary oil changes and damage caused by outdated oil, ensuring maximum efficiency and sustainability in your maintenance.

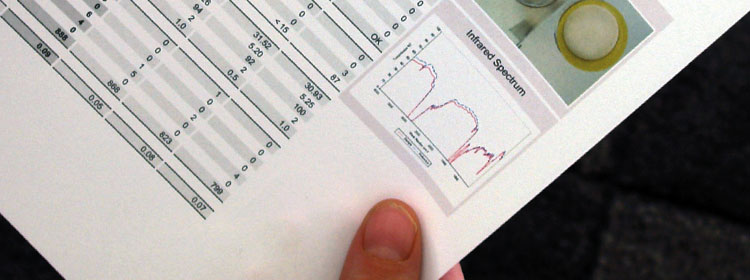

- Reliable detection of when oil is actually used up

- Optimization of oil change intervals to reduce costs

- Understanding the relationship between oil aging and machine condition

- Professional oil change depending on the degree of contamination and oil type

- Reduction of downtime and extension of machine service life

- Sustainable and environmentally conscious use of lubricants

- Maintenance managers and maintenance supervisors

- Technicians and machine operators

- Employees from production and plant monitoring

- Specialists in tribological applications

- Service companies in mechanical and plant engineering

- Operators of hydraulic, transmission, and manufacturing equipment