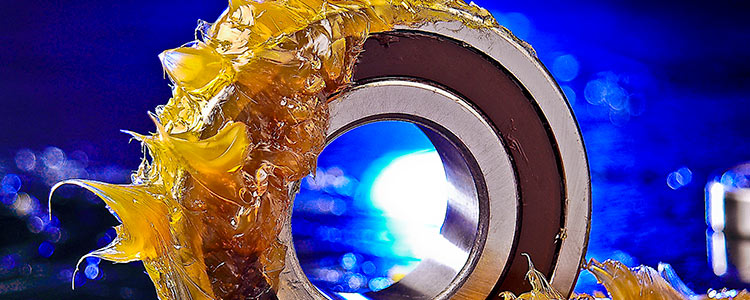

Prevent roller bearing damage through optimal lubrication

Rolling bearing damage is often caused by incorrect lubrication and unsuitable operating conditions. In our intensive training course, technical specialists, sales engineers, and purchasers learn how to avoid long-term damage by gaining a proper understanding of lubricants and their interactions with rolling bearings. Damage patterns are analyzed and causes explained using practical examples. The aim is to enable participants to recognize rolling bearing damage at an early stage and to ensure trouble-free operation through the targeted selection of lubricants and consideration of environmental conditions. Seminar leader Dipl.-Ing. Rüdiger Krethe imparts in-depth knowledge of mechanical engineering and lubrication technology for sustainable bearing reliability.

- Develop a basic understanding of the importance of proper roller bearing lubrication

- Recognizing and avoiding common causes of roller bearing damage

- Understanding interactions between lubricants and bearings

- Learn how to select the right lubricant for different roller bearings

- Teach proper use of lubricants to prevent breakdowns

- Consider environmental conditions and lubricant properties during lubrication

- Be able to correctly analyze roller bearing damage

- Technical specialists from design, service, and sales departments of plant manufacturers and service partners

- Sales engineers and sales representatives of lubricant manufacturers and their distribution partners

- Technical purchasers for lubricants and operating fluids

- Specialist engineers for maintenance and damage statistics

- Employees from tribology and lubrication technology

- Users of lubricants

- Users and designers of roller bearings