The most important facts in brief:

Compressors compress gases. Whether it is air that is required to drive tools, devices or even for breathing, or a wide variety of gases in the chemical industry, refineries or biogas plants: The gas to be compressed, the design of the compressor and the operating conditions lead to very different stresses on the lubricating oil depending on the system.

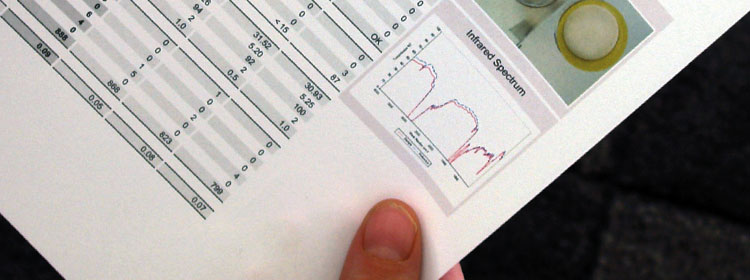

Oil analyses have proven their efficiency and reliability in the monitoring of compressor systems over many years.

This online training series shows you how the professional analysis of increasingly synthetic compressor oils is still a reliable tool for oil and condition monitoring today. The large number of practical examples from various application areas guarantees a high degree of transferability of the knowledge imparted into your daily practice.

Target Group

- Skilled employees and executives working in the field of maintenance

- Engineers, foremen, fitters and service technicians from component and system manufacturers and their service partners

- Sales engineers and sales people of lubricant proucers und their resellers

- Technical purchasers for lubricants and operating fluids

- Application engineers working in mobile labs as well as for on-site condition monitoring and fluid management

- Appraisors and surveyors for damage analysis and machine malfunction

- Technically interested employees who want to extend their knowledge in the areas lubrication techniques and tribology