Detecting, preventing, and efficiently removing deposits in lubricating oil systems

Learn how to detect deposits in lubricating oil systems of turbines and turbo compressors at an early stage, reliably prevent them, and effectively remove them in our online training series. In four compact modules, experienced experts impart practical knowledge about the formation of oil aging products, their influence on plant reliability, and proven measures for safe operation. This ensures that your turbines run smoothly, efficiently, and economically.

Benefit from practical content, clear examples, and in-depth expertise that you can apply directly in your everyday work—for maximum plant availability and extended oil service life.

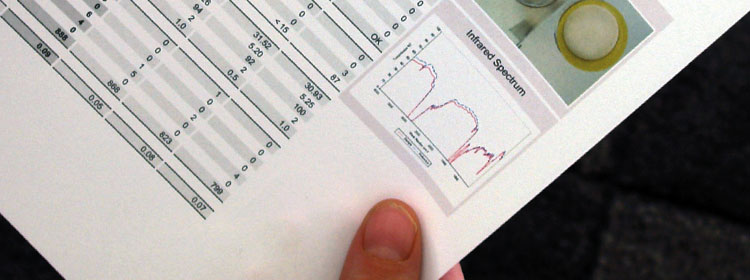

- Understanding causes and boundary conditions for deposit formation

- Detecting deposits in lubrication and control oil systems

- Apply measures for prevention and removal

- Minimize impact on operational reliability and service life

- Targeted use of diagnostic and monitoring methods

- Skilled employees and executives working in maintenance of power plants and chemical companies

- Service technicians, fitters, and commissioning personnel from turbine and plant manufacturers

- Service partners and sales engineers from the lubricant and plant engineering industry

- Technically skilled employees working in construction, serive and sales

- Producers of oil circulation and central lubrication systems

- Technical purchasers and application engineers in fluid management

- Appraisors and surveyors for damage analysis and machine malfunction

- Interested employees with a focus on lubrication technology and tribology