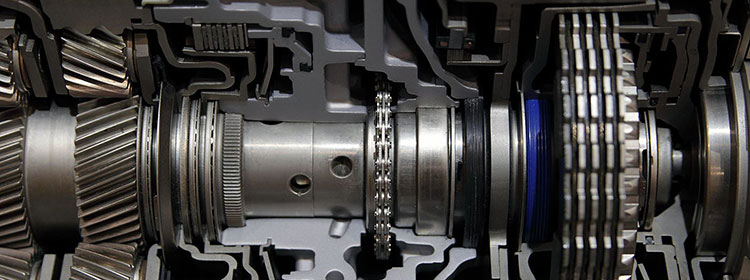

Professional monitoring of gear oils for maximum plant reliability

Gearboxes operate under a wide variety of operating conditions – whether in continuous or intermittent operation, with high torques or in compact designs. Lubrication plays a key role in ensuring that they function reliably. Precisely because components are becoming smaller and smaller and performance requirements higher and higher, regular and professional monitoring of gear oils is essential.

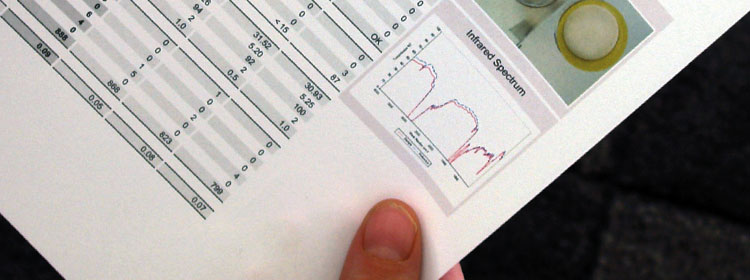

In this video training course, you will learn how to detect irregularities at an early stage by monitoring trends in gear oils. You will learn which parameters are crucial in addition to classic measurements such as viscosity and contamination, what these parameters indicate, and how you can derive specific measures from the results. By interpreting the data correctly, you not only extend the service life of the oil, but also optimize overall plant availability and operational reliability.

- Understanding the relationships between lubrication, oil condition, and plant performance

- Early detection of wear, contamination, and thermal stress

- Establishment of efficient trend monitoring and derivation of recommendations for action

- Use of modern oil analysis for preventive maintenance

- Extension of oil and plant service life through targeted measures

- Increased operational reliability with reduced downtime costs

- Skilled employees and executives working in the field of maintenance

- Mechanics and service technicians of gear and machinery producers

- Technically skilled employees working in construction, serive and sales

- Sales engineers and sales representatives from lubricant manufacturers and their partners

- Technical purchasers for lubricants and operating fluids

- Application Engineer in Condition Monitoring and Fluid Management

- Appraisors and surveyors for damage analysis and machine malfunction

- Technisch interessierte Mitarbeiter mit Fokus auf Schmiertechnik und Tribologie