Learn how to correctly identify and prevent water and air ingress in oil

Avoid costly downtime caused by inconspicuous contamination. In this practical video training series, you will learn how water, air, and foam develop in oil systems, what damage they can cause, and how to diagnose and minimize them in a targeted manner. Each module provides you with in-depth specialist knowledge, application-specific limit values, and clear practical examples—all of which can be directly applied in your everyday work.

This training course will expand your understanding of the relationships between lubricants, operating conditions, and oil quality—and ensure the long-term performance of your equipment.

- Early detection of water and air ingress in oil

- Understanding the causes and consequences of water, air, and foam

- Reduction of downtime and maintenance costs

- Optimization of plant reliability

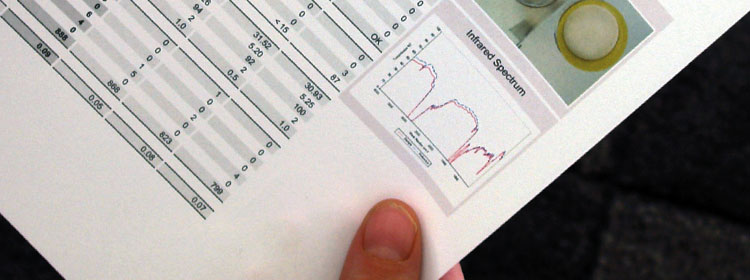

- Application of practical diagnostic methods

- Safe handling of limit values and oil analyses

- Maintenance and service technicians

- Operations and maintenance managers

- Plant operators and engineers in hydraulics or lubrication technology

- Quality and laboratory staff in the field of fluid management

- Technical specialists in oil monitoring and analysis